Is your industrial belt slipping? Belt slippage can lead to unnecessary wear and tear that decreases machine longevity on top of productivity loss. Mechanical issues in the workplace can heavily affect your warehouse production and safety. For industries utilizing conveyor belt assistance, belt slipping is often the cause of decreased production. In fact, according to Pingdom, about 98% of organizations claim only one hour of downtime costs over $100,000.

If you are experiencing frequent belt slippage, it is an issue to tackle as soon as possible and the solution might be more attainable than you think. Keep reading to learn about what causes belt slipping and how to fix it.

Need help with your conveyor belt?

Contact us

What Causes Belt Slippage?

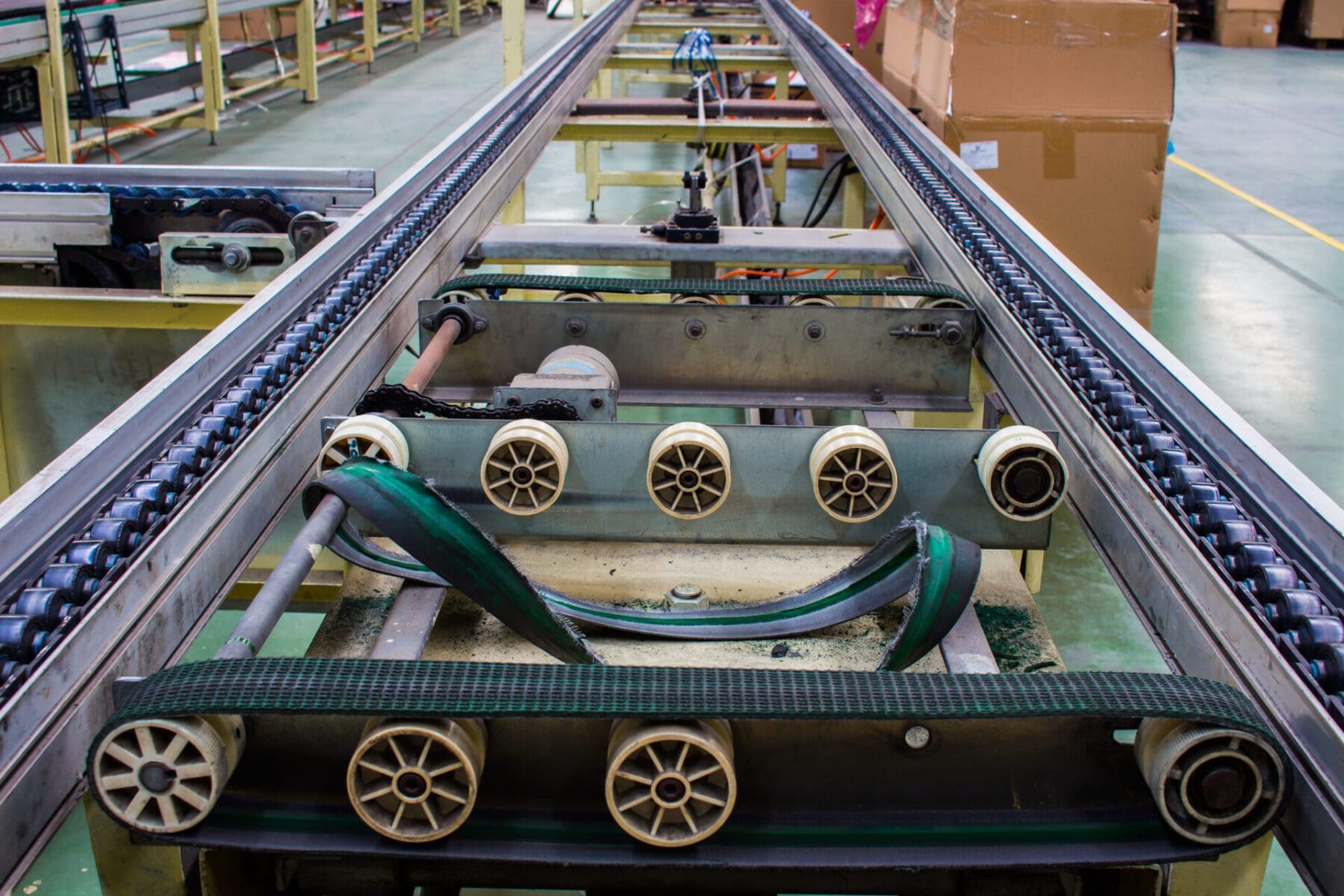

Belt slippage happens when the conveyor belt and pulley don’t have a strong grip. This is typically a result of:

- Improper conveyor belt installation

- Irregularly load.

- Pulley buildup

- Cold temperatures

- Belt damage or wear

- Inadequate lubrication

When a Belt Slippage is Likely to Happen

Some indicators of a loose belt include:

- Belt cracking

- Belt squealing

- Over amperage

- A worn front motor bearing

What Happens If a Belt Is Too Loose?

Frequent belt slipping costs you time and money. When your belt tension is too loose, the excess heat from friction can cause damage to your entire conveyor belt system. Here are the potential consequences of having a loose industrial belt:

- Slippage

- Reduced power transfer

- Increase wear

- Misalignment

- Premature belt failure

To prevent these problems, it’s important to maintain the proper conveyor belt tension with regular inspection and maintenance. Proper conveyor belt tensioning ensures efficient operation and extends the belt’s lifespan.

How Do You Fix a Slipping Conveyor Belt?

A belt will typically start slipping at the drive or head pulley. To correct this, adjustments can be made at the time of installation. These include:

Add Lagging

The first adjustment that can be made to your belt is called lagging. When we refer to lagging, we are referring to the extra material added to the surface of your pulley. This extra material will help combat any slippage.

Tension Adjustments

Be very cautious about conveyor belt tensioning. Too much of anything is never good, so take note that you are not over-tightening your tension. Make your tension adjustments carefully, and remember that belts must make a few rounds before settling into their new tension.

Pulley Replacement

Even though you might have the right belt, you might not have the right pulley. This could either be the wrong size or the wrong pulley altogether. Your system could also benefit from a snub pulley, which increases the length of the belt.

Contact Rainbow Rubber & Plastics to learn more about your pulley replacement options to ensure you get the right pulley for your conveyor belt system.

Clean Your Belt

Finally, your conveyor belt could just need a simple cleaning or minor repair. Just like a vehicle, your conveyor belt needs routine maintenance and inspections. Make sure you’re regularly cleaning your belt, checking for signs of damage, and making repairs as needed.

The Advantage of Conveyor Belt Replacement

If you need a complete conveyor belt replacement, look no further than Rainbow Rubber & Plastics. We have cutting-edge conveyor belt solutions for moving products efficiently without the risk of slowed productivity.

Our conveyor belts have higher tension, wear, and a stronger grip. You can count on moving various conveyor belt products for longer lengths on a single drive.

Get Moving With Rainbow Rubber & Plastics

For over 50 years, Rainbow Rubber & Plastics has been a trusted leader in manufacturing high-quality rubber belts for various industries. As North America’s leading belt manufacturer, we provide custom belting solutions and services that guarantee no belt slipping—so you can keep your production moving in the right direction.

Explore our conveyor belt components and solutions, or contact us for a custom quote.

Comments are closed.

Recent Comments