Woodworking is a popular profession and hobby. No matter your project, there are many types of woodworking machines available to use. Thanks to advancements in the industry, woodworkers have a variety of high-caliber tools and machines at their disposal. Manual and automatic woodworking machines make completing a project simple and effective.

Want to learn the basics about woodworking equipment and the best woodworking machine? Below, we’ll unpack various types of woodworking machines and provide a list of woodworking tools essential to the profession.

Types of Woodworking Machines

If there’s a project you need to accomplish, you may be debating which machine to use. Check out this list of common woodworking equipment and determine which one is the best woodworking machine for your project.

Wide Belt Sanding Machines

Wide belt sanders are popular machines in the woodworking industry. Most commonly used for finishing and deburring wood and metal parts, wide belt sanding machines create even surfaces on solid wood materials (plywood, boards, etc.).

Wide belt sanders are a versatile option for many woodworkers because they have multiple configurations. This sanding equipment can be found in:

- Hardwood floors

- Cabinetry

- Edgebanding

- Profile sanders and shapers

- Deburring

- Metal finishing and stamping

Wide belt sanding machines use sanding belts, consisting of a continuous loop of abrasive material, to smooth and shape different wood materials.

Brushing Machines

This woodworking tool creates a uniform surface finish after undergoing turning, punching, milling, or machining processes. Removal of dust or impurities is a secondary application of brushing machines in woodworking.

Brushing machines are often handheld but the process can also be replaced by wide-belt sanding machines as mentioned above. Wood sanding machines will typically provide more uniform results whereas a handheld brushing machine enables more precision and customization.

Planing Machines

Woodworkers use woodworker planner machines to achieve a precise and consistent thickness on wooden boards. This woodworking machine creates a linear reciprocating motion between the tools and the workpiece. It also has an auxiliary movement (infeed motion) to plan horizontal, inclined, dovetail, T-shaped, V-shaped, and vertical groves.

Often used to create wood joints for cabinetry making or any other type of wooden furniture, woodworking planner machines are an absolute must to create precise cuts. Plus, there exists a wide range of joinery machines from industrial machinery to handheld planning machines.

Wood Lathe Machines

Woodworkers use a versatile tool called a wood lathe, also known as a wood spinning machine, in the manufacturing industry for woodworking applications.

To use this tool, you would typically insert a piece of wood between the two ends of the machine and it will make it spin so you can uniformally share the piece. This is why is it also informally called a wood spinning machine.

A wood lathe is used to cut, sand, drill, face, turn, and deform workpieces. Though smaller and simpler than their metal counterparts, these woodworking machines operate similarly by exposing a rotating workpiece to a stationary cutting tool.

CNC Machines

Computer Numerical Control (CNC) machines are woodworking tools that cut or move material as programmed on the controller. The type of cutting can vary from plasma cutting to laser cutting, milling, routing, and lathes. CNC machines can even pick up and move items on an assembly line.

Below are the basic types of CNC machines:

- Lathes

- Routers

- Milling

- Plasma Cutters

- 3D Printer

These automatic machines enable a faster, more precise, and more uniform woodcut.

Common Types of Woodworking Accessories

These are the major woodworking machines, used daily for all kinds of projects whether that is crafting cabinet doors, boxes, or simple wooden planks. Now the question is, how do these woodworking machines function? Well, there is a key component to the most used woodworking machines: woodworking belts. Let’s introduce the main types of woodworking machine belts you may find.

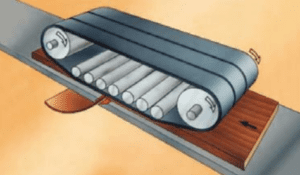

Trailroll Belts

Woodworkers use truly endless feed belts in slicing and super surfacing woodworking machines. They’re mostly used to produce veneer, flooring, and wooden laminates.

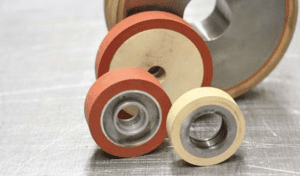

Rubber and Metal Rollers

These components are for sanding, contact rollers, pressure, or feed wheels. They’re also applicable for roller pads, tracks, and molded items for edgebanding, squaring, tenoning, and sanding/calibrating machines.

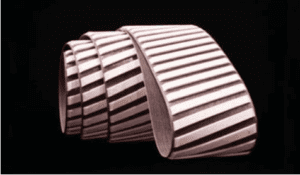

Sandbelt /Sandroll

Truly endless pressure belts with felt chevron or strip profile are used as support belts of the abrasive paper in wide belt sanding machines. Sandbelts are fitted with either diagonal or V-felt stripes.

MoviCart

Safely and effectively transport racks and carts with the Renova MoviCart unit. This accessory reduces forklift traffic and eliminates worker strain.

Woodgrip

These feed belts are for edge and profile sanding machines with an integrally molded v-guide on the inner side. OEM supplier for Delle Vedove, and Makor machinery.

Custom Woodworking Belt Solutions

Rainbow Rubber and Plastics, Inc. is a leading supplier of endless belting and rubber accessories for the North American market. Specializing in high-wear applications, we supply a range of products for the woodworking industry. We provide a solution-based approach to each customer’s manufacturing process and woodworking industrial machinery needs through direct customer engagement.

Rainbow Rubber & Plastics, Inc., provides custom rubber belt manufacturing solutions for other industries as well. Interested in our products? Reach out to us today for more information.

Comments are closed.