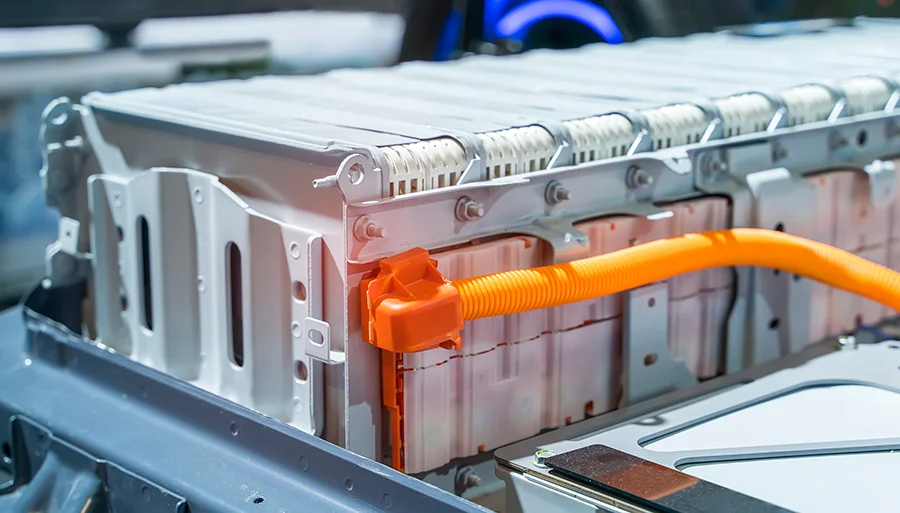

The battery industry has seen exponential growth over the last several years. To streamline operations and meet demands, the battery industry has utilized the use of seamless conveyor belts. These belts have become an industry staple and an integral part of various applications.

Keep reading to learn more about Rainbow Rubber & Plastics’ truly endless belts and how they can benefit your applications.

What Is an Endless Belt?

An endless belt is a conveyor belt that doesn’t have any seams or splices. Unlike traditional jointed belts, endless belts operate on a continuous loop. These belts are defined by their elasticity, durability, and resistance to abrasions and chemicals. Because of their endless construction, there is far less room for error.

How Are Endless Belts Made?

Endless belts are made from needled felt. These belts are produced under tension and are trimmed according to width requirements.

Benefits of Seamless Belts

1. Improved Performance

One of the hallmarks of our truly endless belts is the lack of seams. Their seamless construction helps ensure smooth and consistent operations, minimizing wear and tear, reducing slippage, and improving overall performance.

2. Increased Durability

Seamless belts are more durable than their traditional jointed counterparts. Since these belts have no weak points or splices, the likelihood of premature wear and tear is extremely minimal. This helps improve the longevity of the belt and lengthen its lifespan.

3. Improved Speed

Rainbow Rubber & Plastics’ seamless belts are designed for speed and performance. Time is always of the essence in fast-paced industries like the battery industry. That’s why a speedy belt is critical for those working in such demanding industries.

4. Reduced Maintenance

One of the best parts about our truly endless belts is a reduced need for maintenance. With far fewer breakdowns, industries can focus on other critical aspects of the production process while improving their productivity.

5. Customization

Some industries need custom belting solutions. Seamless belts can be customized to meet specific manufacturing requirements, allowing industries to get the most out of their belting operations. Rainbow Rubber & Plastics can customize any seamless belt to your specific standards.

6. Increased Safety

Safety is our biggest priority at Rainbow Rubber & Plastics. By design, our truly endless belts help reduce the risk of work-related accidents.

Truly Endless Belts Used for Battery Pasting Machines

Pasting machines are used in battery manufacturing and are designed to apply paste on the grids. Our truly endless belts are manufactured with battery pasting machines in mind and can be used for the automatic pasting of battery grids. In other words, they make for a great battery-pasting belt.

These belts can be integrated with pasting machines such as Hadi, Sovema, Wirtz, Mac, or Winkel.

Benefits of Seamless Belts for the Battery Industry

Seamless Belts From Rainbow Rubber & Plastics

Those in the battery manufacturing industry don’t have time to deal with faulty belts. When you choose Rainbow Rubber & Plastics, you’re choosing a company with over 50 years of experience in belting solutions. Start streamlining your belting operations today by asking about a risk-free trial.