Blog

Common Mechanical Issues in the Wire and Cable Industry

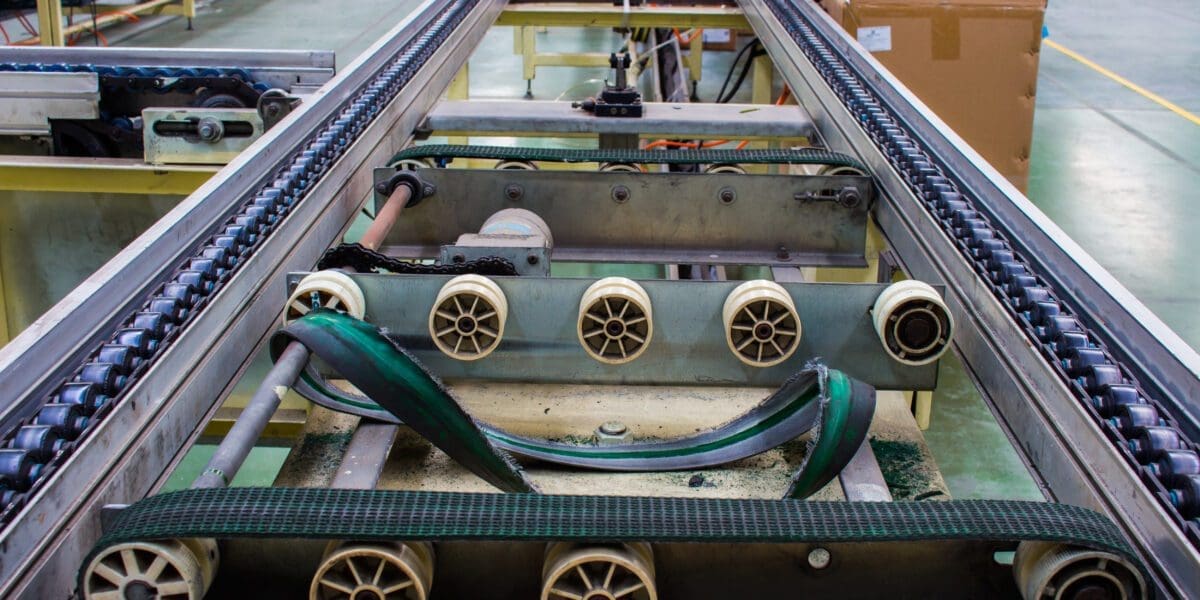

Every mechanical component has an important role in the wire and cable industry. One key component used daily is the belting mechanism. The use of an industrial belt is found across multiple industries and is designed to do everything from processing products to pulling wiring and cables. So when common mechanical issues like belt chatter and slippage happen, the whole

Common Belting Problems: Causes and Solutions

The conveyor belt is used on many types of equipment across multiple manufacturing industries. We know that it’s what drives your industry forward, so when belting issues like blockages, slippage, and mistracking happen, your entire process gets thrown out of order leading to bigger mechanical issues. That’s why we’re here. Keep reading to learn more about common belting problems and

Streamlining Manufacturing Processes With Custom Rubber Belting Solutions

The manufacturing business is complex, but with the right tools, you can streamline your processes. Custom solutions for the wire and cable industry, such as heat shrink end caps, CV gaskets, and extrusion screens, are important in improving equipment performance, safety, and production. Keep reading to learn how you can streamline your processes with Rainbow Rubber and Plastics. Contact Us

Farming Conveyor Belts – Usage of Conveyor Belts in Agriculture

We’ve come a long way from the days of horses and plows. In today’s fast-paced world, farming conveyor belt systems have become the superior method of transportation for agricultural products. Belting systems in the agricultural industry have streamlined the process of vegetable harvesting, packaging, and distributing to retailers around the United States. Let’s take a look at how Rainbow Rubber

Heat Shrink End Caps: A Guide to Proper Usage

From electronics to plumbing, exposed live wires are a risk for any industry. They can cause electrical shocks or spark a fire if not capped. Heat shrink end caps are a simple and effective way to secure seal cables, wires, and pipes. Electrical end caps can also connect wires, ensuring electrical continuity while keeping the wires themselves safe from external

The Benefits of Electric Car Pushers & How Movitruck Is Moving the Auto Industry

Can Power Pushers Improve Plant Efficiency?

Transporting heavy materials around a warehouse is no easy task. Between safety concerns and forklift constraints, moving reels and other large objects without appropriate tugging equipment can put a damper on your plant efficiency. However, there’s no need for your employees to struggle with heavy loads when you can use powered pushers for your tugging equipment. How do they work

Conveyor Belt Slippage – Causes & Solutions

Is your industrial belt slipping? Belt slippage can lead to unnecessary wear and tear that decreases machine longevity on top of productivity loss. Mechanical issues in the workplace can heavily affect your warehouse production and safety. For industries utilizing conveyor belt assistance, belt slipping is often the cause of decreased production. In fact, according to Pingdom, about 98% of organizations

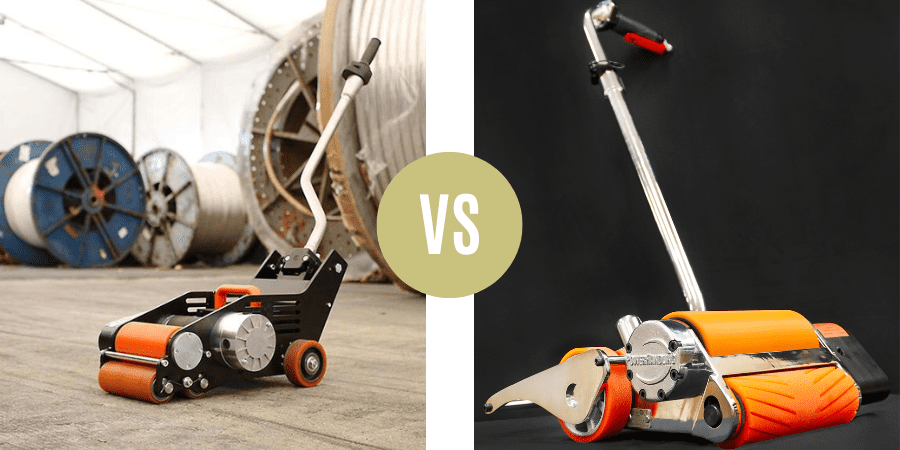

Moviroll vs. PowerRoll: Which One Is Better?

Share Moving reels around the warehouse can be tricky, especially when you’re moving heavy loads. That’s where Renova’s tugging equipment comes in handy. Electric roll movers are designed to handle large and small loads on flat surfaces so that the operator can get from A to B with ease. But which one is the best for your business? Let’s take

Paper Core Manufacturing Optimization – Main Issues & Solutions

Share Core manufacturing often requires heavy machinery and who says heavy machinery says real safety needs. Between operating the different machines, moving products, and navigating around the plant, core manufacturing can be a real challenge. The right belting solution is essential in eliminating unplanned downtime, prioritizing worker safety, and improving efficiency in the core manufacturing industry. Keep reading to see