The manufacturing business is complex, but with the right tools, you can streamline your processes. Custom solutions for the wire and cable industry, such as heat shrink end caps, CV gaskets, and extrusion screens, are important in improving equipment performance, safety, and production.

Keep reading to learn how you can streamline your processes with Rainbow Rubber and Plastics.

Contact Us

3 Ways To Streamline Your Manufacturing Processes

1. Wire and Cable End Caps: Enhancing Product Durability

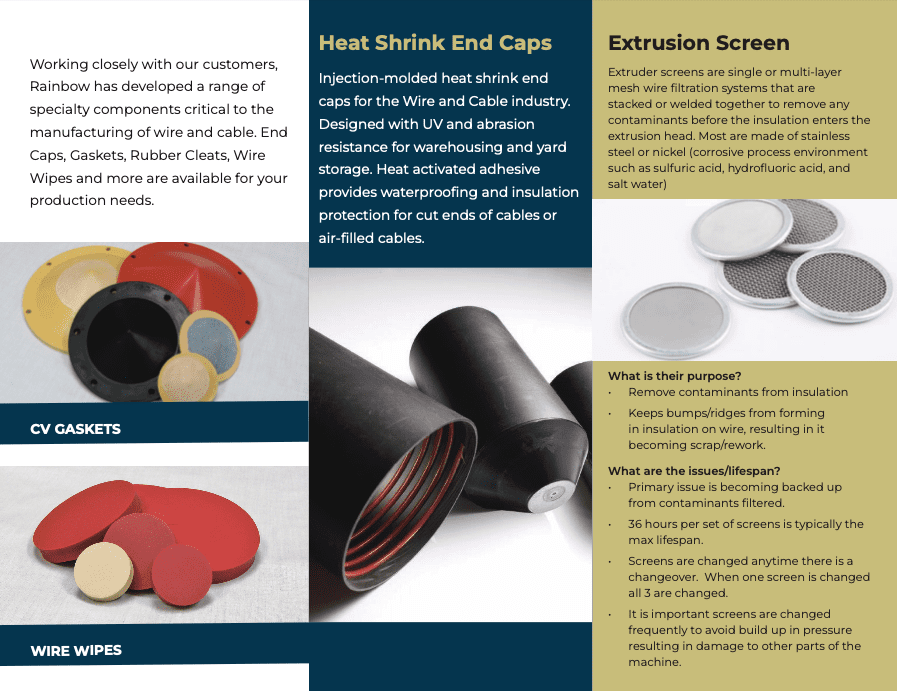

Costly damage from exposed wires and cables can be avoided when using the proper heat shrink end cap. Heat shrink end caps protect your wire and cables from dust, moisture, and debris. All you need is a little heat.

Rainbow Rubbers and Plastics’ Wire and Cable End Caps are meant to protect and extend the lifespan of the wire and cable you produce. At the end of production, simply apply heat to the heat shrink end caps and watch them shrink to form a tight seal around your cables. Our heat shrink end caps are resistant to cracks, abrasion, and UV light—all of which can damage your cables and create hazards.

2. CV and Wire Wipe Gaskets: Improving Production and Efficiency in the Wire and Cable Industry

Gaskets play an essential role in preventing leaks and forming a seal between two surfaces, usually the parts of a machine or system. Rainbow Rubber and Plastics specializes in providing custom gasket solutions for wire and cable manufacturing, offering a range of CV seals and wire wipe gaskets.

Our CV seals are available in sizes from three to 16 inches and crafted from durable rubber or silicone rubber. Plus, our wire wipe gaskets are available in various diameters and thicknesses, and provide effective leak prevention for wire and cable manufacturers.

3. Extrusion Screens: Optimizing Production Processes

Extrusion machinery is used to shape plastic or rubber into continuous profiles; this includes wires and cables. The die of the extrusion machine is what shapes these materials; however, contaminants like dirt and dust might enter the die without a screen.

Extrusion screens help filter out these contaminants, capturing them and preventing them from entering the die. Without an extrusion screen, your final product may exhibit some defects.

Another reason to use an extrusion screen is to protect the extruder machine. Extrusion screens act as a barrier between the machine and its environment, which can help prolong its lifespan. They can also reduce clogs and minimize downtime, leading to enhanced productivity.

Contact Us for Custom Rubber Belting Solutions

The best way to improve your production and output is by investing in custom solutions.

Whether you need to protect your equipment or improve your manufacturing process, Rainbow Rubber and Plastics is here to help. We’ve been catering to the wire and cable industry for over 30 years—and we can help your manufacturing process, too.

Get the tools you need to streamline your processes; trust Rainbow Rubber and Plastics. Start now by getting in touch with a Rainbow Rubber representative. Don’t forget to ask about a risk-free trial for all of our products.

Contact Us

Comments are closed.

Recent Comments