Moving reels around the warehouse can be tricky, especially when you’re moving heavy loads. That’s where Renova’s tugging equipment comes in handy. Electric roll movers are designed to handle large and small loads on flat surfaces so that the operator can get from A to B with ease. But which one is the best for your business?

Let’s take a closer look at what powered pushers are and how they can benefit your warehouse workers.

Contact Us

Powered Pushers: What Are They & How Are They Used?

Powered pushers move heavy-duty tugging equipment within a warehouse or plant environment. Commonly used as car pushers or roll movers, they are convenient, easy to operate, and take up much less space than bulky forklifts.

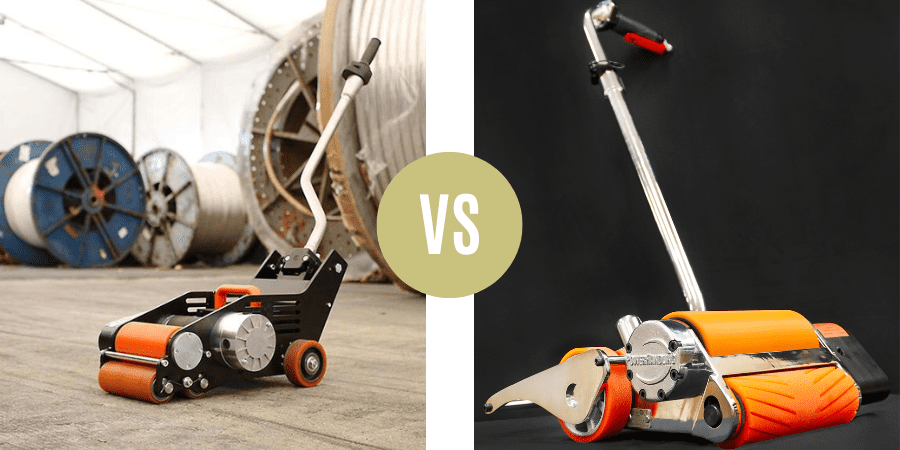

Moviroll vs. PowerRoll: What’s Better?

Now that you know what a roll mover is, let’s dig in a little deeper. After all, there are plenty of options in the market when it comes to tugging equipment. How do you know what pusher to choose? Let’s dive into the key differences between the biggest players in the market: Moviroll and PowerRoll pushers.

Versatility

While PowerRoll can be used for a few different types of rolls and reels, its range is overall limited due to how it latches on to your load. Unlike PowerRoll, Moviroll is a great forklift alternative that can be used for any reel. Moviroll’s tugging equipment can move thousands of pounds of material, including cars and trucks.

Battery Duration

If battery duration is a concern, then your ideal choice is Moviroll. PowerRoll has a battery life of eight hours before needing replacement. While that can usually last you for most of the work day, having to recharge it every time can be a pain. Moviroll on another hand, can handle between 60 and 120 loads before requiring one battery charge. This means that you can easily use Moviroll several shifts at a time.

That’s another win for Moviroll!

Weight

Moviroll can handle a thrust force of up to 200 tons, whereas PowerRoll can handle up to 75,000 pounds so about 37,5 tons. This is why Moviroll is the preferred powered pusher for moving extremely heavy loads, including large vehicles.

Practicality

Both Moviroll and PowerRoll-powered pushers are great forklift alternatives. They are easy to use, able to perform well in narrow spaces, and can be operated without the need for a special license. We’ll give additional points to Moviroll as the commands are much easier to understand and make it extra easy to operate. This makes a Moviroll-powered pusher an excellent choice for saving time, money, and space while increasing warehouse efficiency.

Safety

Finally, Moviroll amplifies safety in warehouses and production plants nationwide. Manually moving loads is dangerous and can result in major workplace injuries. Moviroll makes it possible for operators to effectively move heavy loads without risking their safety.

Read also: Can Power Pushers Improve Plant Efficiency?

Conclusion

While both tugging equipment options have their advantages, Moviroll’s powered pusher can not only handle a greater load, but can be used for a wider range of applications, and lasts much longer before needing a battery charge.

Investing in a forklift alternative certainly enables both greater flexibility and safety. Powered pushers are great for effectively moving heavy loads without risking the workers’ safety.

Increase Your Warehouse Productivity With Rainbow Rubber & Plastics

For over 50 years, Rainbow Rubber & Plastics has been designing specialty rubber belts for specific applications. We are also a proud supplier of Renova’s battery-driven powered pushers. Get your warehouse productivity in check while keeping your employees injury-free with a heavy-duty powered pusher.

Contact Rainbow for an in-plant demonstration today.

Comments are closed.